genie s 45 service manual

genie s 45 service manual

Safety Rules and Precautions

Always follow safety guidelines to prevent serious injury or death. Wear personal protective equipment and ensure proper hazard identification. Adhere to lockout/tagout procedures and machine-specific safety protocols.

1.1. General Safety Guidelines

Always follow safety rules to avoid accidents. Wear required personal protective equipment‚ such as hard hats and safety glasses. Ensure proper machine lockout/tagout procedures are in place before maintenance. Familiarize yourself with hazard identification and risk assessment protocols. Refer to the Genie S-45 service manual for specific safety guidelines and precautions to ensure safe operation and maintenance of the equipment.

1.2. Personal Safety Equipment

Always use personal safety equipment when working with the Genie S-45. This includes hard hats‚ safety glasses‚ and steel-toe boots. High-visibility clothing is also recommended. Proper PPE ensures protection and prevents injuries. The service manual provides detailed guidelines on required safety gear for both operation and maintenance tasks.

1.3. Hazard Identification and Risk Assessment

Identify potential hazards like electrical components‚ hydraulic systems‚ and machinery movement. Assess risks to ensure safe operation and maintenance. Use the service manual to understand specific dangers and implement control measures. Regular inspections and adherence to safety protocols minimize accident risks. Always be aware of your surroundings to prevent injuries or equipment damage.

Machine Specifications and Features

The Genie S-45 XC offers a maximum working height of 45 feet‚ compact design for indoor/outdoor use‚ and a spacious platform for two workers and tools.

2.1. Technical Details of the Genie S-45

The Genie S-45 XC is a telescopic boom lift with a maximum working height of 45 feet. It features a compact design for indoor and outdoor use‚ a spacious platform for two workers‚ and tools. The manual provides detailed specifications‚ including weight‚ dimensions‚ and operational capabilities‚ ensuring optimal performance for various tasks. Proper maintenance and repair procedures are also outlined for longevity.

2.2. Key Components and Their Functions

The Genie S-45 features a robust boom structure for stability‚ a hydraulic system for smooth operation‚ and a control panel for precise movements. The platform is designed for safety and comfort‚ while the joystick enables easy control of boom functions. Regular inspection and maintenance of these components are crucial for ensuring safe and efficient operation of the machine.

Scheduled Maintenance

Regular inspections‚ lubrication of moving parts‚ and hydraulic system checks are essential to ensure optimal performance and safety. Follow the recommended maintenance schedule strictly.

3.1. Daily Inspection Checklist

Conduct daily checks of the Genie S-45‚ including tire pressure‚ hydraulic fluid levels‚ and control functions. Inspect wire ropes‚ boom sections‚ and platform components for damage. Ensure all safety decals are visible and legible. Test all safety devices and alarms before operation. Document findings and address any issues promptly to maintain safety and efficiency. Always follow the manufacturer’s guidelines for a thorough inspection process.

3.2. Weekly and Monthly Maintenance Tasks

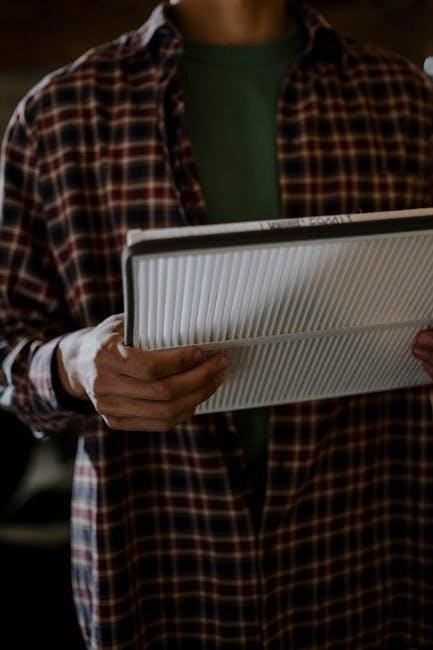

Perform weekly checks on hydraulic fluid levels‚ boom lubrication‚ and wire rope condition. Monthly‚ inspect the platform‚ Check control system functions‚ and ensure all safety devices are operational. Clean and lubricate moving parts as specified. Replace air filters and inspect battery connections. Refer to the service manual for detailed schedules and procedures to ensure optimal machine performance and safety. Regular maintenance prevents downtime and extends equipment life.

Troubleshooting Common Issues

Identify fault codes and address common issues like hydraulic malfunctions or control system problems. Check connections‚ consult the manual‚ and perform diagnostics to resolve faults efficiently.

4.1. Identifying and Diagnosing Fault Codes

Fault codes on the Genie S-45 are indicated through blink codes or alarm messages. Refer to the service manual for code interpretations. Diagnose issues by checking system connections‚ hydraulic pressures‚ and electrical components. Consult the troubleshooting guide for specific fault resolutions. Reset alarms following procedures outlined in the manual. Always ensure proper safety measures are in place during diagnostics.

4.2. Hydraulic and Electrical System Problems

Hydraulic issues may include fluid leaks or valve malfunctions. Check for damaged hoses and test valve operation. Electrical problems often involve faulty connections or sensors. Verify all wiring and connections‚ and consult the schematic for troubleshooting. Use a multimeter to test electrical components. Always follow proper lockout/tagout procedures before performing repairs to ensure operator safety and system integrity.

Repair and Replacement Procedures

Follow detailed procedures for repairs‚ using genuine parts. Replace components like key switches and hydraulic cylinders carefully. Ensure proper alignment and torque specifications for secure installations. Always refer to the manual for specific instructions and safety guidelines to maintain machine functionality and operator safety.

5.1. Replacing the Key Switch

Ensure the machine is powered off and in a safe state. Remove the key switch by noting its orientation and using a soft metal drift to drive out the retaining pin. Carefully pull the switch out and disconnect the wiring harness. Install the new key switch‚ ensuring proper alignment and secure installation. Reconnect the wiring harness and test the machine to confirm proper operation. Always refer to the manual for specific instructions and safety guidelines.

5.2. Hydraulic Cylinder Removal and Installation

To remove the hydraulic cylinder‚ ensure the machine is on level ground and all pressure is released. Use a soft metal drift to drive out the barrel-end pin‚ then carefully pull the cylinder out of the boom. For installation‚ apply lubricant to the pin and align the cylinder properly. Secure it with the retaining pin and test the hydraulic system for leaks. Always wear protective gear and follow manual guidelines for safe procedures.

Torque and Hydraulic Specifications

Adhere to recommended torque values and hydraulic pressure settings to ensure optimal performance. Failure to comply may result in equipment damage or operational instability.

6.1. Recommended Torque Values

Always use the torque specifications outlined in the Genie S-45 service manual to ensure proper machine assembly and operation. Incorrect torque values can lead to equipment damage or failure. Refer to the manual for specific bolt and fastener requirements‚ and use a torque wrench to apply the recommended settings accurately. Adhering to these values is crucial for safety and performance.

6.2. Hydraulic System Pressure Settings

Always refer to the Genie S-45 service manual for specific hydraulic system pressure settings. Ensure pressures are within the recommended operating range to avoid system damage. Use a pressure gauge to verify settings and never exceed the maximum pressure rating. Adjustments should only be made by trained personnel to maintain machine stability and performance. Proper pressure settings are critical for safe and efficient operation.

Platform and Boom Maintenance

Regularly inspect the platform and boom for wear or damage. Clean debris and lubricate moving parts to ensure smooth operation and extend equipment lifespan.

7.1. Platform Inspection and Cleaning

Inspect the platform for damage‚ wear‚ or corrosion. Clean all surfaces‚ removing dirt and debris. Check for loose bolts or components and tighten as needed. Use mild detergents to avoid damage to finishes. Ensure proper drainage to prevent water accumulation. Regular cleaning prevents rust and maintains structural integrity. Always refer to the service manual for specific cleaning products and methods recommended for the Genie S-45.

7.2. Boom Lubrication and Alignment

Lubricate all pivot points and moving components regularly to ensure smooth operation. Use high-quality grease recommended by the manufacturer. Proper alignment of the boom is critical for accurate movement and load stability. Check the alignment periodically and adjust as needed using specialized tools. Refer to the service manual for specific lubrication intervals and alignment procedures to maintain optimal performance and extend equipment life.

Joystick and Control System Repairs

Inspect the joystick for wear or damage. Test functionality by checking all movement directions. Replace faulty components or the entire joystick if necessary. Ensure proper alignment and calibration for precise control.

8.1. Testing and Replacing the Joystick

To test the joystick‚ ensure all directional movements function correctly. If faulty‚ disconnect the joystick from the control system and replace it with a new unit. Secure the replacement firmly‚ reconnecting all electrical connections precisely. Test the system post-installation to verify proper operation and responsiveness. Follow the manufacturer’s guidelines for replacement procedures to maintain safety and performance.

8.2. Adjusting Control System Sensitivity

Adjust the control system sensitivity by accessing the joystick control box. Use a multimeter to measure electrical outputs‚ ensuring they align with specified values. Gently turn the sensitivity adjustment potentiometers to achieve desired responsiveness. After adjustments‚ test all directional movements to confirm smooth operation. Refer to the service manual for precise torque specifications when tightening connections. If issues persist‚ consult a certified technician for further assistance.

Fault Code Reference Guide

Consult the fault code reference guide to identify and diagnose issues. Understand blink codes‚ error messages‚ and system alarms. Reset alarms per manual instructions to restore normal operation.

9.1. Understanding Blink Codes

Blink codes indicate specific faults on the Genie S-45. Each sequence of blinks corresponds to a particular error. Refer to the manual for code meanings‚ such as one blink-pause-two blinks‚ which signifies a specific system malfunction. Understanding these codes helps in diagnosing and resolving issues efficiently‚ ensuring timely repairs and maintaining machine functionality.

9.2. Resetting System Alarms

To reset system alarms on the Genie S-45‚ follow the specified procedure. Turn the key switch to the “OFF” position‚ wait a few seconds‚ and then restart the machine. Some systems may require pressing and holding specific buttons during startup. Always consult the manual for model-specific instructions to ensure proper reset and avoid unnecessary system malfunctions.

Additional Resources and References

Access the Genie S-45 service manual for detailed specifications and troubleshooting. Download PDF manuals from official sources. Contact technical support for assistance with repairs and maintenance.

10.1. Genie S-45 Service Manual Downloads

The Genie S-45 service manual is available for download in PDF format from authorized distributors. It covers models S-40‚ S-45‚ and S-45 TRAX‚ spanning various serial numbers. Ensure you download the correct version for your machine. Visit official Genie websites or trusted service manual platforms to access the document. Always verify the source to ensure authenticity and safety compliance.

10.2. Contact Information for Technical Support

For technical assistance‚ contact Genie’s customer support at 1-800-535-2008 or visit www.genielift.com. Their team is available to address inquiries‚ provide troubleshooting guidance‚ and offer repair support. Ensure to have your machine’s serial number and model ready for efficient service. Genie’s support network is dedicated to helping you maintain optimal equipment performance and safety.